clamp on ultrasonic flow meter installation guidelines

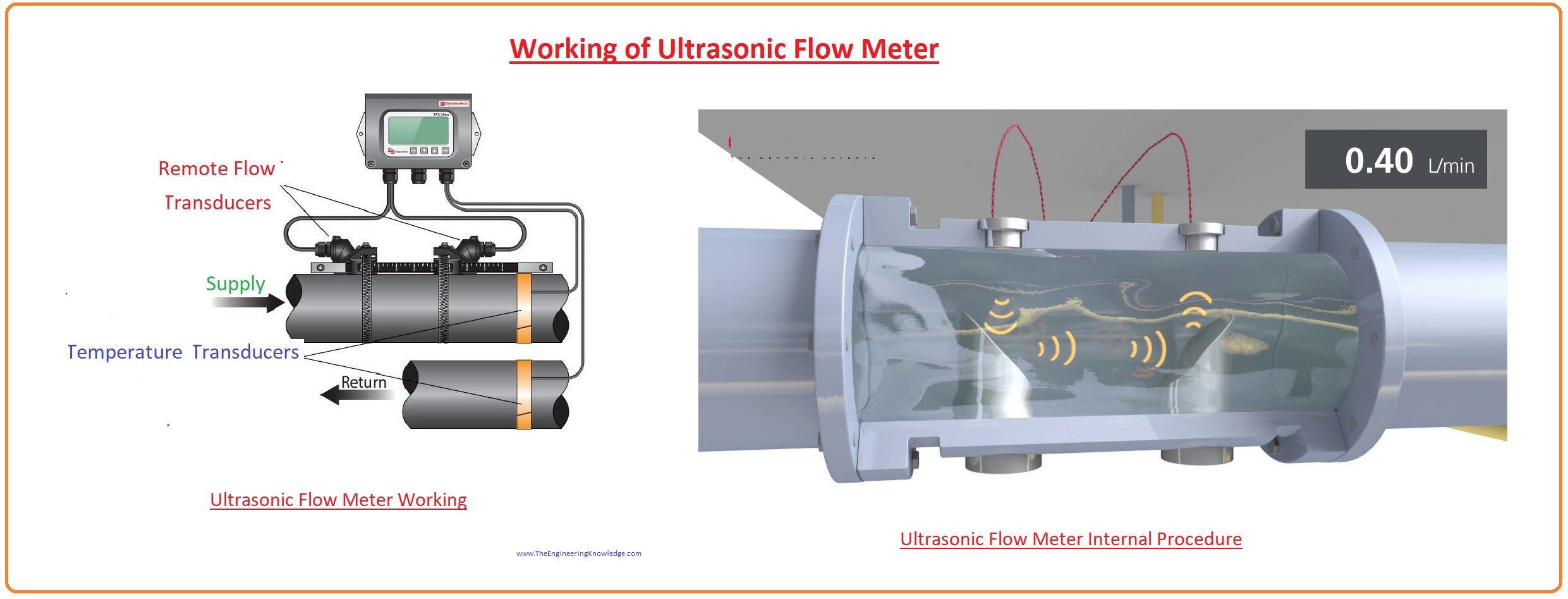

Clamp-on ultrasonic flowmeters are among the most cost-effective technologies for measuring the volumetric flow rate of liquids. Clamp- on transit-time ultrasonic flowmeters can provide bi-directional flow measurement and allow for installation without interrupting production or cutting into process piping.

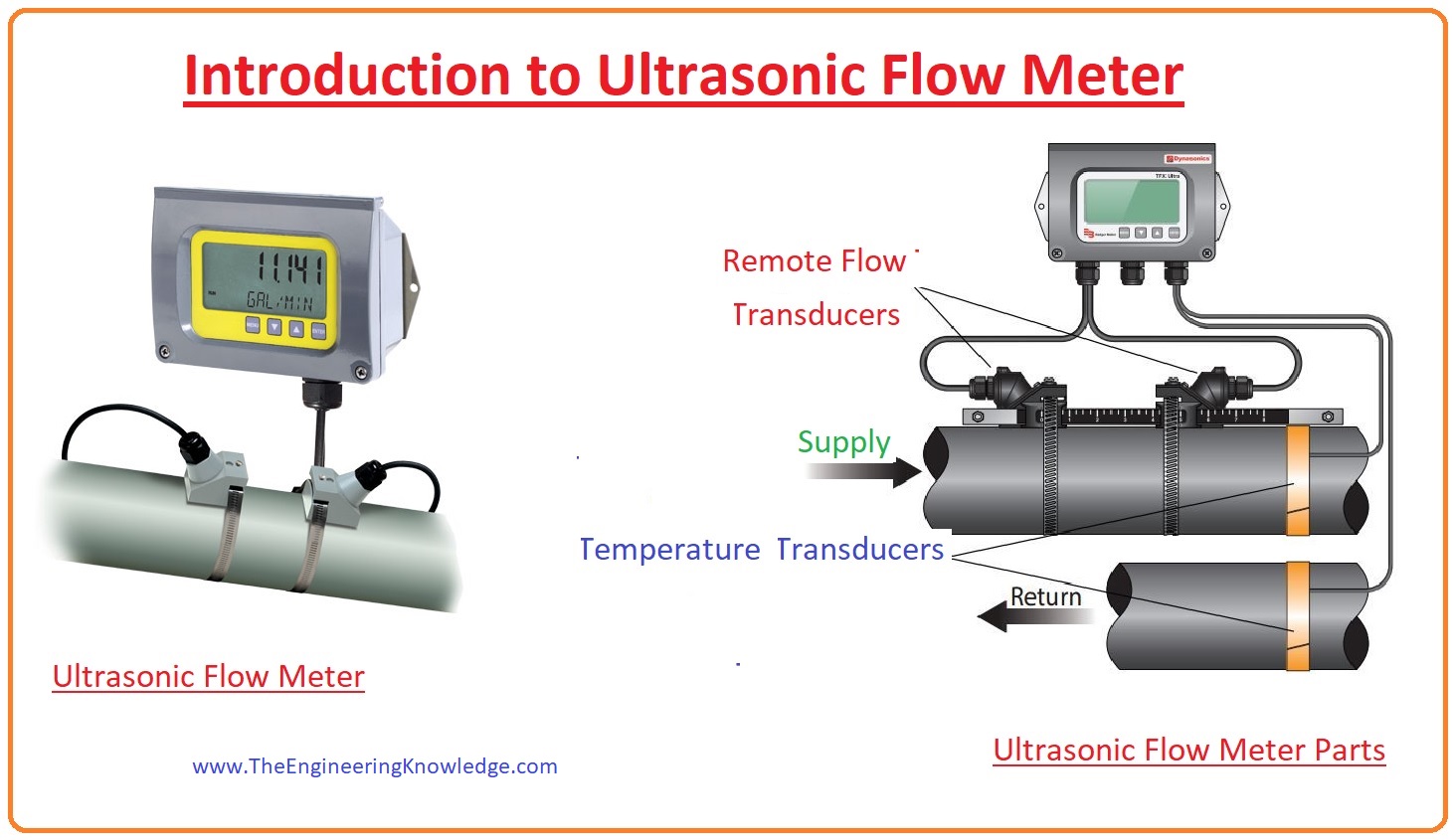

Ultrasonic Flow Meter The Engineering Knowledge

Tri-Clamp Turbine Flow Meter.

. In the first of our application notes for ultrasonic clamp on meters it is astoundingly clear that manufacturer meter quality plays a significant part in attaining accurate flow measurement results. The meter is housed in an aluminum enclosure with silicone. Next-generation clamp-on technology for process industries offers improved user-friendliness and easier installation.

As the ultrasonic sensors are simply clamped on the pipe surface Katronic ultrasonic flow meters can be installed without the need to break into pipelines. It is suitable for measuring the volumetric flow of liquids in a wide variety of applications including bi-directional flow applications. 13 TYPICAL F-4300 FLOW METER The F-4300 Ultrasonic Flow Meter utilizes clamp-on signal transducers that mount on the outside wall of the pipe.

Browse our Equipment Guide categories to find and contact your manufacturer. Liquid turbine flow meter calibration procedure. Turbine flow meter advantages and disadvantages.

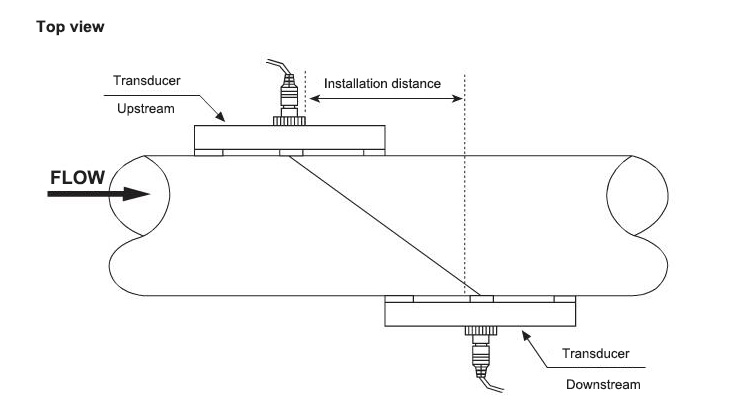

Understanding Installation Problems with Ultrasonic Clamp On Flowmeters. Do not connect transducers to rigid conduit. If enough grease is not applied or the transducers are not clamped to the wall tightly the precision of measurement may be effected.

Turbine flow meter working principle. Wafer Turbine Flow Meter. The F-4300 Ultrasonic Flow Meter utilizes clamp-on signal transducers that mount on the outside wall of the pipe.

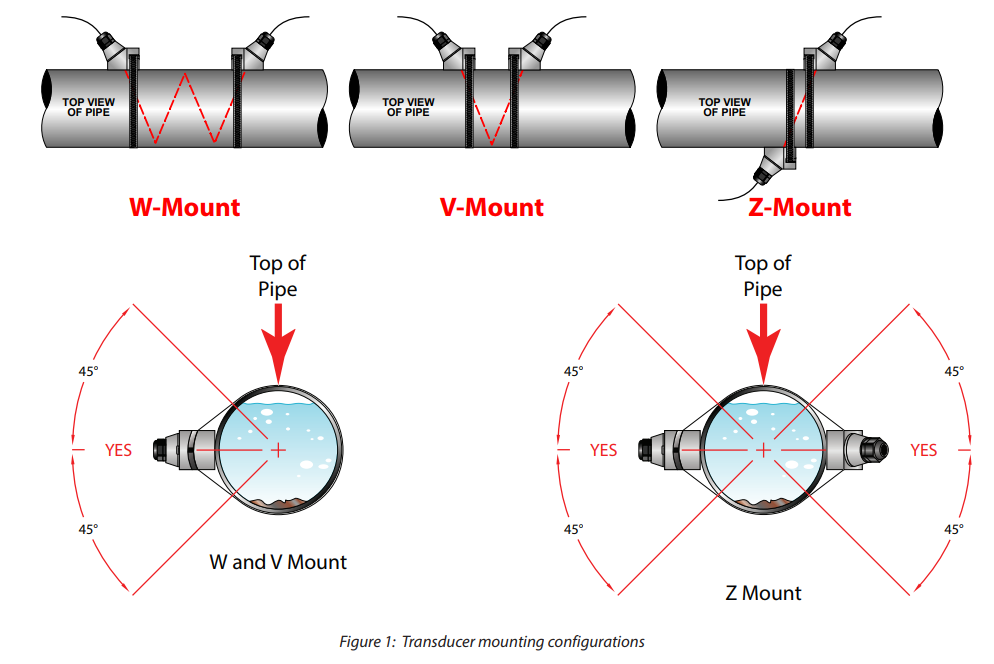

Locate an optimal position where the straight pipe length is sufficient. In later parts we will be discussing installation effects in more detail with traverse type setup coupling pastes pipe sizes particulatebubbles pipe condition and. REFLECT MOUNT DIRECT MOUNT.

Flow Meter Installation Guidelines. January 29 2020. Male Thread Turbine Flow Meter.

For successful ultrasonic flow meter installation locate the flow meter in a sheltered position away from falling water. Pipe Type Ultrasonic Flow Meter. 17 ADDITIONAL HARDWARE THAT MAY BE REQUIRED Flex conduit may be required to connect transducer to rigid conduit.

Flexim a globally recognized leader in the m. As a leader in the field of clamp-on ultrasonic flow measurement FLEXIM offers the ideal flow meter solutions - even for the most demanding challenges. The non-invasive nature of the sensor installation couples with sufficient accuracy and low maintenance requirements to give this.

U-F-M delivers flowmeters that are easy and quick to install. Within a few minutes you have set up an accura. Ultrasonic Flow Meters HOW IS THE FLOW METER INSTALLED.

Ultrasonic flow meter with clamp on sensor. The meter is housed in a NEMA 4X IP67 polycarbonate wall-mounted enclosure with a built-in user. Apply a sufficient amount of grease at the installation area and clamp the transducers tightly on the pipe.

Clamp on ultrasonic flow meters have become more popular throughout the water food chemical process and building services industries due to their ability to measure in-situ flow rates from outside the pipework with optimum accuracy. General Installation Guidelines for TT Liquids Flowmeter. About Ultrasonic Clamp-on Flow Meters for liquids.

During ultrasonic flow meter installation care must be taken to ensure that the end fittings on the meter are not stressed during use. As their name suggests clamp-on sensors are mounted to the exterior of a pipe eliminating the need for line alterations. Clamp on ultrasonic flow meters are ideal for applications when system.

The grease is used to eliminate any gaps between the transducer and the pipe wall. The spacing value shown on menu window M25 refers to the distance of inner spacing between the two. Ideally flexible tubes should be used.

Producing consistently accurate results with an ultrasonic flow meter depends heavily on a proper installation. This video shows the installation step by step. Ultrasonic flow meters are utilized throughout the fluid processing industries as well as for compressed air and energy monitoring.

This non-contact solution also eliminates pressure loss and potential meter fouling. This ultrasound signal is sent into a. 03 to 12ms 30 ms for high precision sensors Pipe must be completely full within the sensor installation volume for accurate flow measurement All flowmeters assume a full pipe.

Ultrasonic flow meters use sound waves at a frequency beyond the range of hearing typically 05 1 or 4 MHz. The price depends on the type and range of flows that can be measured. It is suitable for measuring the volumetric flow of liquids in a wide variety of applications including bi-directional flow applications.

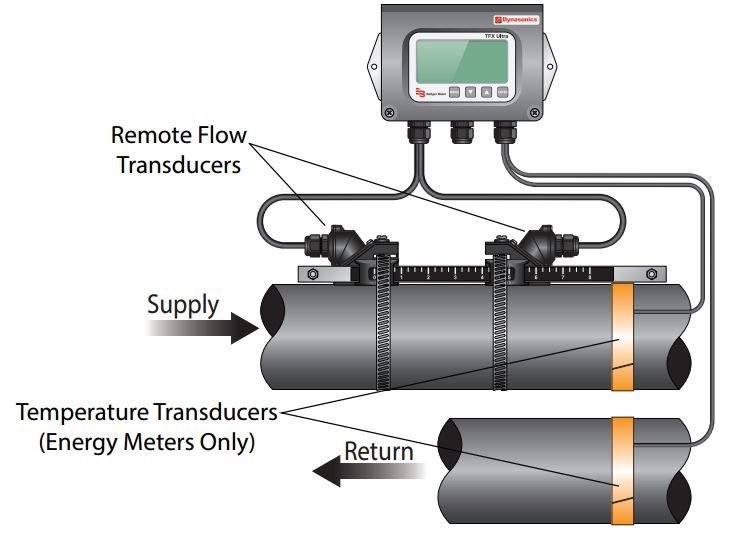

The sensors are fixed to the pipe using metal chains straps or mounting rails. Ultrasonic flow meter installation guidelines Steps to the installation of the transducers. Ultrasonic flowmeters consist of clamp-on transducers that are attached on the outside wall of the pipe with flowing water Figure 1.

Hardware requirements vary by pipe size and material. Oil Turbine Flow Meter. Installing a Clamp-on Ultrasonic Flow Meter.

Ideally the meter should be installed with straight lengths of tube either side for a. Up to 15 cash back Clamp-on Ultrasonic Flow is a non-intrusive technology that is applied to the outside of process piping. At the time of preparation of this fact sheet the price for a single unit ranged between 2000 and 13000.

The following list shows some of the details one must consider in installing a pressure-based flow meter element. The ultrasonic flowmeter has a wide range and the flow rate can usually be from 1 ms to 30 ms or a larger flow rate under the condition of ensuring high measurement accuracy. Turbine flow meter installation guidelines manual.

Ideal for clean liquid applications this transit-time measurement technology reduces installation downtime and provides significant cost effectiveness when compared to inline flow measurement equipment especially in larger pipe sizes. Typical MINIMUM straight pipe requirements are. Minimum measuring range.

ONICON clamp-on ultrasonic flow meters typically require installation hardware. It is suitable for measuring the volumetric flow of liquids in a wide variety of applications including bi-directional flow applications. The flow velocity and direction are accurately determined.

Therefore the selection of its diameter can generally be smaller than the size of the main pipeline which can reduce the overall investment in the straight pipe. 12 TYPICAL FP-4400 FLOW METER INSTALLATION The FP-4400 Portable Clamp-on Ultrasonic Flow Meter utilizes clamp-on signal transducers that mount on the outside wall of the pipe. Perhaps the most common way in which the flow measurement accuracy of any flow meter becomes compromised is incorrect installation and pressure-based flow meters are no exception to this rule.

Clamp On Ultrasonic Gas Flow Meters

How To Install Clamp On Ultrasonic Flowmeters I Mega Instrument

How To Install Clamp On Ultrasonic Flowmeters I Mega Instrument

![]()

F 4300 Clamp On Ultrasonic Flow Meter Thermal Energy Measurement System Onicon Flow And Energy Measurement

U1000mkii Fm Fixed Clamp On Ultrasonic Flow Meter Micronics

Clamp On Ultrasonic Flow Meter Xtsensors

6000 Series Portable Ultrasonic Flow Meter

Portable Ultrasonic Flow Meter Installation Tutorial How To Solve No Signal Message Youtube

Clamp On Ultrasonic Flow Meters Installation Guidelines Rms Engineering

Clamp On Ultrasonic Flow Meters Installation Guidelines Rms Engineering

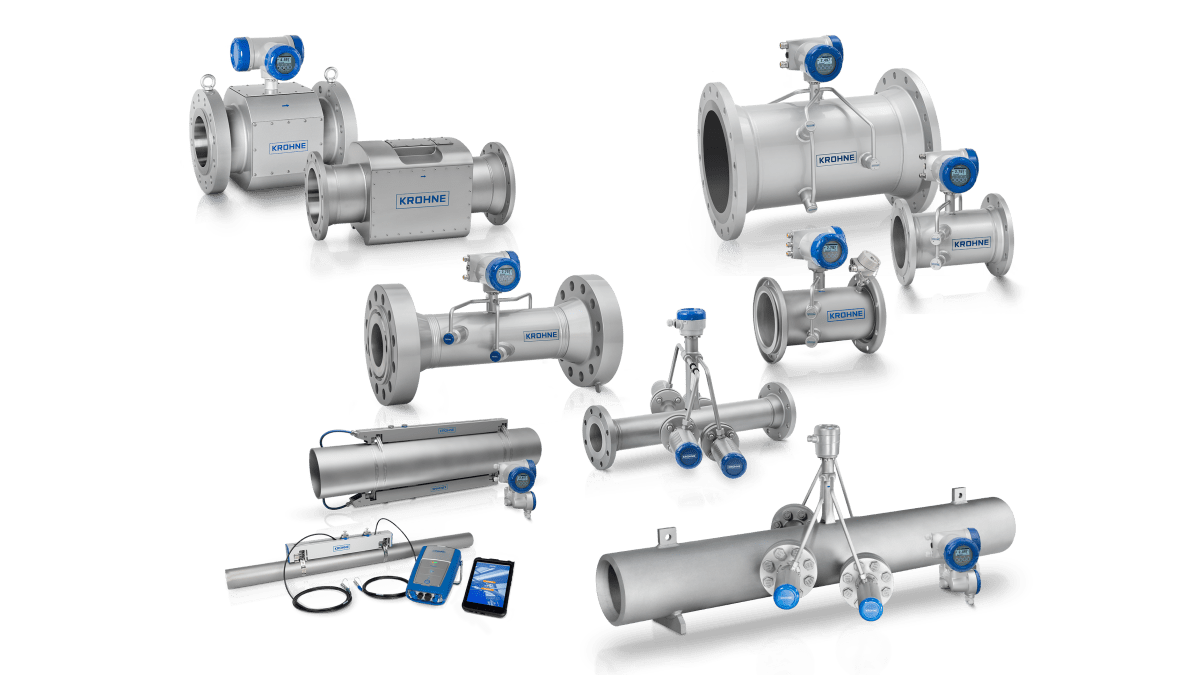

Ultrasonic Flowmeters Krohne Group

How To Install Clamp On Ultrasonic Flowmeters I Mega Instrument

Ultrasonic Flow Meter The Engineering Knowledge

Portable Clamp On Ultrasonic Flow Meter For Water Ato Com

Si 3403 Clamp On Ultrasonic Flow Meter Sino Inst

How To Install Clamp On Ultrasonic Flowmeters I Mega Instrument

How To Install Clamp On Ultrasonic Flowmeters I Mega Instrument